June 28, 2019

3D Printing and Nagoya University

A 3D printer creates three-dimensional objects from digital data. They're called printers because they layer printed surfaces to create three dimensions. Printing using metal as a kind of ink makes it possible to create metal parts in complex shapes impossible with conventional machining, and thus 3D printing is expected to revolutionize manufacturing, with the competition in development having reached a frenzy.

It was Nagoya University graduate Hideo Kodama who first devised this groundbreaking technology. More than 40 years after graduation, he is returning to the campus as a student this summer. He will participate in the School of Science's 3D Workshop course to learn together with high school students and other members of the general public how to actually create objects with a 3D printer. During graduate school he was involved in an extensive glacier inventory in the Himalayas, then joined a public research institute, and soon after submitted a patent application for what we know today as a 3D printer. After his invention garnered absolutely no recognition whatsoever, however, he left the world of research, distanced himself from 3D printing, and has since spent his days as a busy patent attorney. Now that he finally has time for something other than work, Kodama would like to use the device himself to discover how the technology has progressed over the past 40 years. His pioneering invention was not taken advantage of in Japan, and as a result the United States has become a leader in 3D printing. Why was Japan unable to leverage this technology? Starting with this question, a number of lessons emerge.

Hideo Kodama at his office, which is decorated with paintings by Meidai Professor Emeritus Keiji Higuchi, Kodama’s own graduate school professor

Hideo Kodama at his office, which is decorated with paintings by Meidai Professor Emeritus Keiji Higuchi, Kodama’s own graduate school professor

Kodama submitted a patent for an "automatic method for fabricating cubic shapes" in April 1980, three years after joining the Nagoya Municipal Industrial Research Institute (NMIRI). He was 30 years old. But then in 1985 he switched to a job at a patent attorney firm. Kodama worked as a researcher for less than 10 years. In that short time he struck upon a great invention, and then decided to end his career in research.

Kodama graduated with a degree in applied physics from the Nagoya University School of Engineering in 1973. He had planned to join a company, but became interested in Himalayan glacial research after hearing about it from a friend in the School of Science, and so continued into graduate studies at Nagoya University's Institute for Hydrospheric-Atmospheric Sciences. But after standing face-to-face with the Himalayan glaciers, rather do than large-scale research that lasts 100 or 200 years, he realized he was better cut out for research more easily verifiable through smaller experiments. Coached in his mindset towards research by glaciology authority, Professor Keiji Higuchi -- who advised him, "Think for yourself" and "Value imaginative ideas" -- he finished his masters course in four years.

The mission of NMIRI where he started working in 1977 was to provide technological and research-and-development support to small-to-medium enterprises. Kodama began by observing different projects at random, trying to find what to do. Three themes stood out for him. One of those was creating a device that could output the results of 3D CAD (computer-aided design), which was a new technology at the time. With 2D, it's easy to check something designed by a computer by printing it out. Kodama thought that 3D design also needed an output, since one couldn't have a concrete image of something without actually seeing it in solid.

Then, at a printing technology exhibition, a device caught his eye that created blocks for newspaper printing. It spread photosensitive resin on a glass plate, atop which was laid a film with letters and other characters cut out of it. When ultraviolet light was applied, only the cutout sections would harden and the characters would rise up on the plate. This would then be added to a rotary press to print the newspaper. It struck him while riding the bus home: Adding more layers of resin could create a 3D shape.

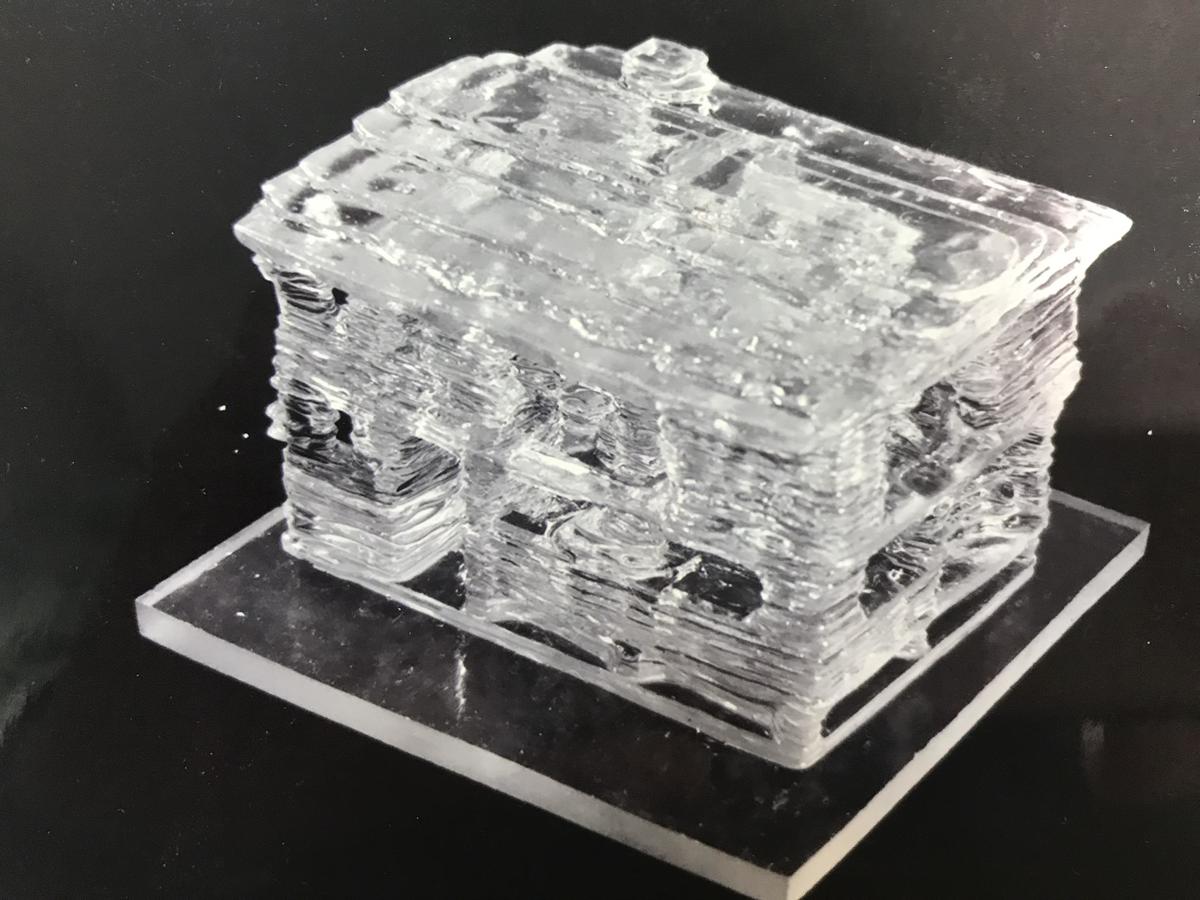

Wanting to test it immediately, he returned to the expo and asked for some of the liquid resin used in the demonstration. He immediately began experimenting, as he did not want to allow what he was so kindly given go to waste by letting it harden. The process is done in water, and when he attempted to create the shape of the Himalayan Mountains, he was astonished to see their forms rise up beneath the water. To try a more complex shape next, he went with a model of a house, as he thought it would surely be useful for an architect to show an actual building model instead of just the blueprints. Again, he was successful. It even contained furniture and a staircase. This was in February 1980. Two months later he applied for a patent. Over the next year he published papers in Japanese and American academic journals, spoke to machine tool makers, and presented at academic conferences.

The model house, 5 centimeters tall and formed by 27 layers of resin each 2 millimeters thick. Kodama destroyed the original model, and only his photos remain

The model house, 5 centimeters tall and formed by 27 layers of resin each 2 millimeters thick. Kodama destroyed the original model, and only his photos remain

He received no response. Even the research institute didn't think much of it, and because 2-millimeter layers made the model quite rough, there was also no interest from manufacturers who had competed to develop manufacturing precision down to 1000ths of a millimeter. It was a technology he thought could be so useful, yet nobody felt the same. Kodama then learned that an engineer at U.S. company 3M had published an article on a similar concept he developed to produce items aboard spaceships. He exchanged information with him, but the company eventually decided it wasn't worth patenting and never applied. He received not one positive reaction.

Kodama says it was a difficult period where he questioned his sense as a researcher each day. He quit his job in research and resolved to become a patent attorney instead.

But there were moments when he wondered if things could possibly have been different. An engineer from a major electronics manufacturer, who had heard Kodama made a presentation at the fringes of an academic conference in Tokyo, visited NMIRI to see an experiment. Kodama eagerly readied the experiment and gave him a performance, but the engineer left without showing any interest. So, it was a failure after all. Kodama was hugely disappointed.

Long afterwards, he learned that the manufacturer had applied for a number of patents for related technologies. The engineer seemed actually just bluffing.

"I was just a young man of around 30. If he had shown even a single hint of interest, maybe things would have been different." Of course the company likely had their own circumstances. "But it's really bad to have done that to a young guy, isn't it?"

When Kodama addresses students, he tells them, "Don't be fooled by adults."

When he changed jobs, Kodama wanted to sever any lingering attachment to his research, so he destroyed the prototype device and the models he had taken so much care to make, like the Himalayas and the house, and threw away all his notes.

The first person to implement this technology was American engineer Charles Hull. He applied for a patent in 1984 and founded the company 3D Systems in 1986. Kodama learned of this in 1987, when a company requested his help in researching into "this interesting American patent where things grow like bamboo sprouts out of a liquid." It was just like the patent Kodama himself had applied for, but the request was purely coincidence; the person in charge had graduated from Meidai, and had thus sought an attorney who was also a Meidai graduate. Kodama had no remaining documents on the patent, and when he ordered a record of the application, he learned that the deadline of an additional request for examination, which was required for his patent to be formally granted, was just three months earlier. It felt as if the goddess of fate had smiled on him, then coldly turned him away.

Kodama met Hull in 1995 when they were both awarded the Rank Prize, a British award for achievements in optoelectronic engineering. They were awarded together on the grounds that Kodama had developed the rapid prototyping theory to create 3D objects from digital data, while Hull expanded on and implemented that theory. Kodama praises Hull, saying, "Through conviction he managed to make rapid prototyping a reality." Even if one understands the theory, to realize it requires various experimental devices, and software must also be developed. That requires funds in the region of tens of millions of yen. "He became persuasive enough to raise money and turn it into a business. It was really incredible," Kodama himself admits honestly, "rather than just come up with the theory, I probably should have tried more in showing what it could do."

On the other hand, researchers at the Osaka Prefectural Research Institute of Industrial Technology (now the Osaka Research Institute of Industrial Science & Technology) also applied for a similar patent shortly before Hull. This essentially shows that, after Kodama, similar ideas popped up elsewhere, including at 3M in the U.S., but to envision the future possibilities and take it one step further was no easy feat.

In 1986, the year after Kodama became an attorney, he spent time in the U.S. training at the patent office. He had no idea during his stay, but looking back, at that time 3D Systems was making headlines in America with their new equipment. If he had paid more attention to the news and realized this, he likely would have requested the additional examination for his patent.

As a patent expert, Kodama says there are many things to learn from this experience.

His first mistake was not having applied for a patent abroad. As a result, he was unable to receive any royalties if an overseas company used his patent. And then, even though he applied for a patent in Japan, he didn't request an additional examination and lost his opportunity to have it granted.

Even more regrettable was that Kodama had other ideas based on the original patent, but the American venture got to them first. In short, as his research progressed, it occurred to him that other combinations may work besides hardening resin with light. He remembered a lecture by Professor Ryoji Ueda, who was known for his research on ultrafine metal particles while Kodama was at the School of Engineering, and devised a plan for an experiment to sinter fine metal powder. But he abandoned his research on the theme and shelved the plan after that. Around 10 years later other venture company in the US implemented the same idea, making it possible to manufacture complex metal parts impossible with normal machining processes -- for example creating spiral-shaped channels for coolant water inside a piece of metal. Above all, they expanded into things like airplane parts, where price is no object, and it has become a big business for them. Kodama laments having not publicized his plan, but he had only thought of it as a way to visualize digital data -- a sort of tool to draw a picture -- and hadn't gone as far as to envision its use in manufacturing.

Kodama applied for the patent himself but, looking back, if he had used an experienced attorney at that stage, he would have been made aware of the ins and outs, and things may have turned out differently.

Engineer Ryusei Yamaguchi. On the right is the most popular type of 3D printer that is made in Japan, with its lid open. Also pictured are two low-priced Chinese printers, and one older model of American printer

Engineer Ryusei Yamaguchi. On the right is the most popular type of 3D printer that is made in Japan, with its lid open. Also pictured are two low-priced Chinese printers, and one older model of American printer

So, when Kodama returns to Meidai as a student this summer, he'll be taught by engineer Ryusei Yamaguchi from the School of Science Equipment Development Office. Yamaguchi says he has been very nervous since receiving Kodama's application.

Yamaguchi came to Meidai in 2015 after about eight years working in development at a machine manufacturer. The Equipment Development Office heads development of devices that are used in various kinds of research at the School of Science, from elementary particle research to observation satellites, and even biological experiments. Soon after starting, Yamaguchi noticed they had 3D printers that were hardly being used. Resin has an expiration date set by the manufacturer, and is only good for up to a year after purchase. The resin they had left was already expired. What a waste of a good piece of technology. That being said, he wasn't really sure how to use it.

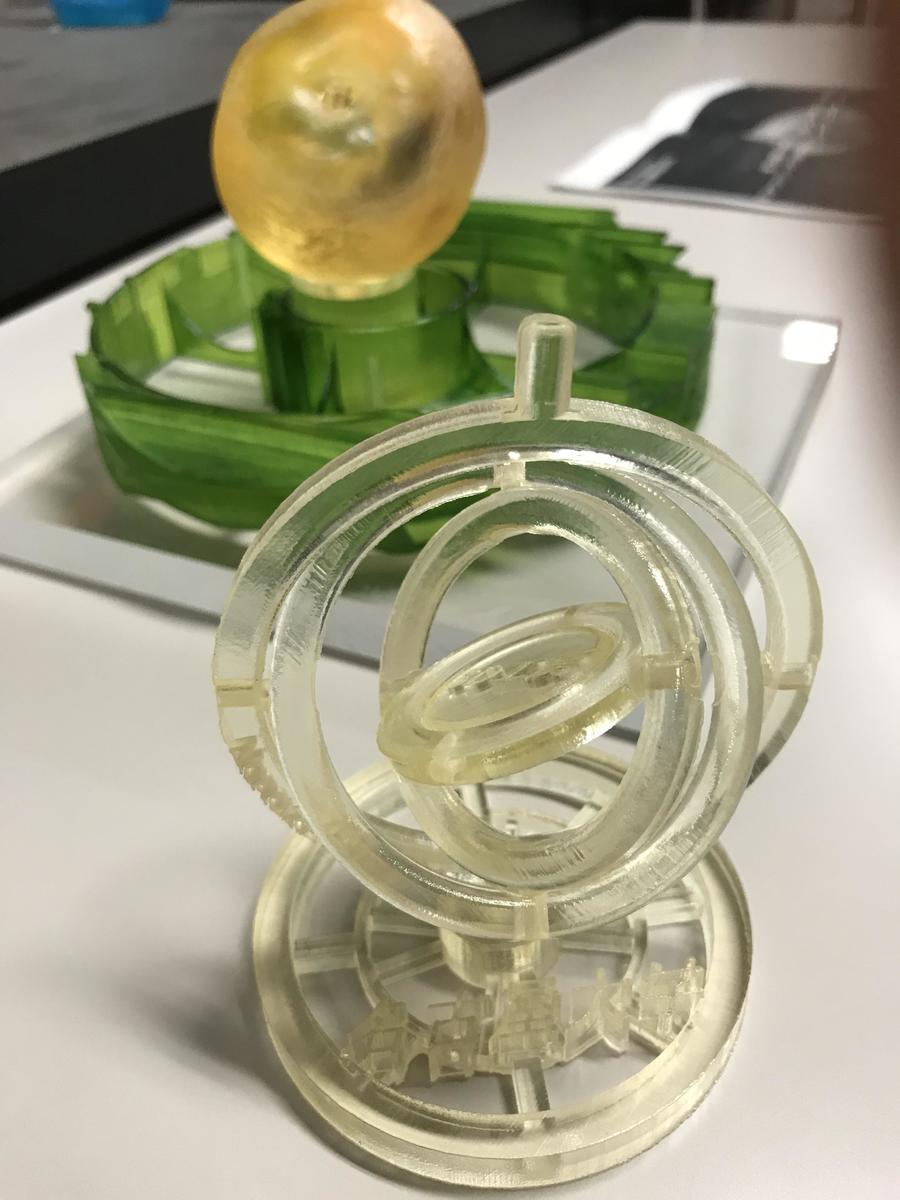

And then in 2016, he started the open 3D Workshop that Kodama will join this summer. Applications are accepted from the general public, and participants learn how to convert data created on a computer into something a 3D printer can use, then actually print an object. Yamaguchi himself learned through this workshop the advantages of 3D printers and how to use them. As a result, the number of researchers utilizing 3D printers has increased in the School of Science and beyond.

The printers used in the workshop function like an inkjet printer, spraying resin that is then hardened by UV light. This is exactly the theory that Kodama devised. But this will be his first time starting with creating data on a computer. "I'm looking forward to learning from Yamaguchi," he says.

A gyroscope produced at the 3D Workshop. These kinds of shapes can also be created automatically

A gyroscope produced at the 3D Workshop. These kinds of shapes can also be created automatically

After hearing Kodama's story, it made me think. Was there no path where his great invention could have been better utilized? And what about the importance of valuing and encouraging the ideas of young people?

Thinking back to my own days as a newspaper reporter at the beginning of the 1980s, lead movable type was still being used to print newspapers. Workers would arrange each and every piece of type into articles to create the printing plates. Not long after that, the resin printing plates Kodama had seen began to be used. They are said to have revolutionized newspaper printing. The healthier working environment was also made possible by eliminating lead. Learning that this same technology became an inspiration for 3D printing really moved me. Typographic printing by laying ink on an uneven surface of course began with Gutenberg, and is said to be one of humanity's three great inventions. This has now been replaced by offset printing, with its lack of bumps and grooves. Now 3D printing could be considered the newest evolution in printing technology.

Finally, I asked Kodama about his dream. "My dream is to work on an invention with the same impact as 3D printing, as an attorney," he said. I hope the students at Meidai will work hard to help this alumni achieve his dream.

Subscribe to RSS

Subscribe to RSS